The Ulm archive is finally getting somewhere in English, hopefully more images to come, please look, some remarkable work.

http://www.hfg-archiv.ulm.de/english/the_collections/hfg_collection/objects_photos.html

I knew you'd like it , its a ...

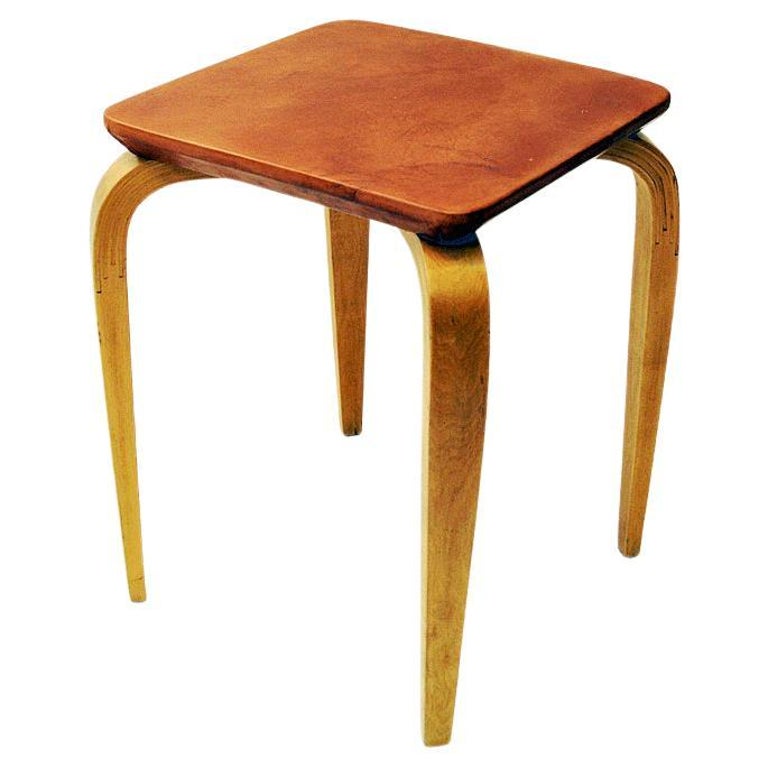

I knew you'd like it , its a fascinating little bit of bent work but I do wonder about its real strength. Thanks for posting your sketch again, I think about it from time to time.

Just pulled a heap of reject (look fine to me) cedar vertical blind slats out of storage and if I get time will have a play doing something like the bentwood connection.

I suspect

that the laminated node would be somewhat flexible if stressed, while mine would be more rigid -- up to the point of failure. Flexibility -- like a tree -- has saved many a structure -- like a tree, for instance.

I'd like to see what you'd do with your slats. You'll soon find out how far they can be bent before snapping ! It's only by virtue of the extreme thin-ness of the veneers that plywood can be bent as, say, Aalto does.

.

I've played with the slats before, its good stuff and there are mountains of it at blind manufacturers, they reject stuff that I can see nothing wrong with, oh well their loss is my gain. Its 3mm thick and doesn't bend to a very small radius, 190mm is the smallest I've pushed it to, and the dreaded black handed polyglue is the only thing it seems to like that I'm prepared to use.

I think the Ulm study might be ok, I'm just not sure, it also depends on the adhesive and as you say its felxibility. I've used a rigid and flexible urea formaledhyde before on some bentwood stools and although it takes hours longer to cure I always prefered the flexible stuff.

I saw a video many years ago of the Paimio chair being made, I can't recall it exactly but it looked like it was done with hot steel rollers rather than conventional molding, it was very interesting and I'd love to know more about Arteks process if anyone has any information.

No time to play with the cedar today unfortunately, getting organised and doing wonderfully exciting stuff like patching drywalling and carpentry takes precedence, blah.

If you can get hold of the Birkhauser book 'timber construction manual' its worth a look, some fantastic stuff in there though a lot of it is over the top of my head, it shows some pretty innovative European and Japanese work from the 60's to now and is very inspiring sowing such thing as double helix viewing platforms and stunning laminated beams spanning entire sports stadiums.

If you need any help, please contact us at – info@designaddict.com