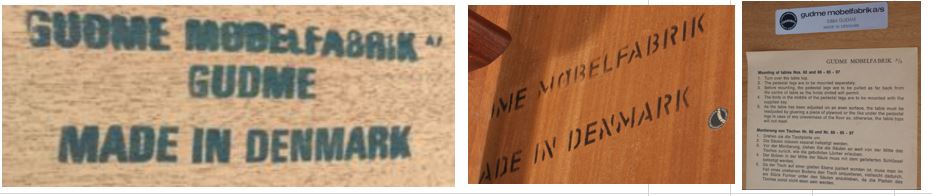

I recently picked up this table for a couple bucks that I believe to be Niels Moller for Gudme Mobelfrabrik (marked Gudme Mobelfrabrik on the underside), but would like to confirm that.Also, this table is in obvious need of attention and am looking for some advice on refinishing. I'm not new to refinishing by any means, and I'm looking for a balance between durability, aesthetics, and future maintenance. In the past I've used a combination of Waterlox, Arm-R-Seal, and beeswax on teak with great results, but I'd like to hear others' experiences with refinishing rosewood in particular.

I do believe this table is Gudme Møbelfabrik. I remember seeing marked specimens.

I have never seen any evidence for the N.O. Møller attributions of this model that are so prevalent around the internet, and I would definitely characterize them as suspicious. Niels Otto Møller was not an architect for hire, but rather the family patriarch of J.L. Møller's Møbelfabrik and designed *most* of the company's models in a very iterative fashion over years. Thus it runs contrary to this archetype for him to have done "design" work for anybody else.

I would treat the N.O. Møller for Gudme attribution with a great deal of doubt. Unless someone actually produces reliable evidence that this was a N.O. Møller design I will not believe it.

And I will add that even a number of eponymous design credits in the high era of Danish Modern are doubtful _with_ reliable evidence in hand. Occasionally it happens that one can find conflicting documentation that says that a known, third party designer was responsible for a design and then other documentation saying that the owner of the company was responsible for the design.

See here for more: http://www.designaddict.com/forum/General-discussion/Secret-Designers

I suppose this is a bit off topic, buy I think it helps illuminate the doubt that must accompany the idea that N.O. Møller designed for other firms.

I have the catalogue from GUDME and there are NO mentions or referrence to Niels Moller doing any work for the company. The ONLY contamination is in the images for the tables.

They are shown with MOLLER chairs but that is not a surefire reason to link Moller to Gudme!

see attached scans of the Gudme intro page and a similar table to yours.

Thanks for the catalog reference. That pretty much settles it that NO Møller was not involved at all.

One could speculate that the article about the company tells us who designed Gudme's product. At least I think the case is strong enough that a scrupulous person could say "attributed to Johannes Jensen" with a straight face...

Thanks all for the ID knowledge.

@tktoo I'm not sure exactly how to test the finish, but I believe it's shellac judging by the severity of the checking. Whatever it is I plan on stripping it with a soy based stripper.

@mgee76. The process I like to use is 3 coats Waterlox, 2 coats Arm-R-Seal, lightly sanding in between coats with 400 grit. Then polish it up with some beeswax and #0000 steel wool. This gives a lot of protection while not leaving a plastic look in my opinion.

Has anybody had any experience with the Sam Maloof products?

@Danish-homestore I just want to note that your scan isn't the exact table I have. Mine being a rectangular top on a similar base. I've yet to find a similar example with the rectangular top.

@mgee76 The times I used the combination of Waterlox and Arm-R-Seal I've been refinishing a main table top that was worn to match the leaves which were in fine condition. I also used the same combo to partially refinish a credenza (top & drawer faces). In those particular instances it worked great.

This piece is a little different so I don't have to use the same combo because I'm going to be stripping the whole table anyways due to the high gloss finish throughout. However, I do want some added protection to the top. There are already some veneer chips on the edge of one of the leafs that I need to repair and stabilize. Though I do think the existing finish did more harm than good, so I'm really hoping it's not going to fall apart when I start stripping it.

Exactly. And I've only ever used Waterlox Original. I was interested in using Sam Maloof Poly/Oil Finish, but on the Rockler website it says it's specifically not suggested on rosewood, so I guess that rules it out. The only other rosewood furniture I've refinished was a coffee table that I ended up simply oiling with 100% tung oil and waxing with great results. I'm just not sure if that's an adequate process for a dining table.

M, if it is indeed shellac on the table, it'll come off with denatured alcohol. If what you're calling checking is a network of fine cracks in the film, and it is shellac, you could probably reamalgamate the finish to an even, restored film using only denatured alcohol. If the existing finish is "alligatored" with wider traction cracks, it often means that there has been a thick, oily layer added over an improperly cured or incompatible finish and stripping is probably in store.

Shellac is hard enough to offer good abrasion resistance by itself, but doesn't provide the most durable finish for a dining table as it is somewhat susceptible to moisture and alcoholic beverage spills. It is, OTOH, an ideal intermediate layer between rosewood and varnish as it effectively eliminates adhesion issues sometimes experienced with oily woods. In other words, if your plan is to top coat with a varnish anyway, there's no need to completely remove shellac.

Further, if the finish on the base is in good shape, rubbing it out with #0000 steel wool will leave a nice satin sheen similar in appearance to an oiling and waxing and would certainly require much less effort than a refinish. Just a thought.

@tktoo the checking I'm refering to is consistent with the alligatoring that you point out. In the last picture of the top I posted you can see the moisture damage to the finish that makes me think it has to be completely stripped.

After a bit more research, I think the best route might be a lacquer finish, since an oil based finish like Waterlox or Arm-R-Seal will have adherence issues because of the natural oils of rosewood. The only other option I see is tung oil & wax finish.

If you need any help, please contact us at – info@designaddict.com