Hello AllJust picked up this Paul McCobb Planner desk in what I think is a tobacco stain.It's in immaculate condition, besides the top, which has been used so much the finishing appears to have been rubbed away.Looking for ideas as to what my next step should be. Obvioulsy I have to sand the top part of the desk down to the raw wood, but is there any chance I'll be able to match the tobacco stain of the rest of the desk?Should I sand away down to the raw wood on the whole desk? Ideally, I'd like it to have that natural amber/blonde look you typically see with these planner desks.Any help would be most appreciated. I've searched the forums and come upon a few threads dealing with these desks, but, from what I understand, the desks in need of the refinishing needed to be striped of paint?Thanks in advance to all you people with more knowledge than I!  <img class="wpforo-default-imag

<img class="wpforo-default-imag

I'm sure somebody has better advice than I do... but you might be able to thin and spread that topcoat around with some lacquer thinner. I've had success doing similar things. You'll end up with a lighter shade of the color when you're done, but if you can achieve uniformity, you could then lightly sand and apply some tinted wiping varnish. I don't know.... just a thought.

When I got very lucky and found mine, it had been painted with two coats of crappy latex paint! The first one was white and the second was red! I totally stripped and scraped it down to bare wood -sanded and added a nutmeg gel coat stain with 3 coats and then a satin topcoat or two and it turned out gorgeous! I use a glass top for protection. The wood tone isnot blond, but a warm honey in the medium value range. They are worth the time and labor to redo as the results are stunning as I found that to be in my case. Also, the legs etc. are easy to remove for this process. Happy sanding!

Hey Terry

Thanks for the response and sorry for the late reply!

That's great to hear! I'm excited to get this thing started. Did you do all your sanding by hand? Any tips? I haven't done wood working since I was a kid building CO2 cars and I'm horrified I'll screw this thing up.

I'm assuming, stripping off the original finish is the first step and then a heavy sanding of the entire surface area of the desk comes next?

At this point, I think I'd like to just finish it with clear varnish to retain that amber golden look of the wood, rather than restain. Should make the process a little simplier, no?

Anyway, thanks again!

Joe

Hi there!

Joe, yes I stripped everything down to bare wood and hand sanded all of it. First with 150 then 220 grit. I was surprised how warm the nutmeg finish came out on what I thought was a pretty unfinished wood look. You can always test the area first and then you can try a stain if you don't get the exact match for your base. I have had great luck both with gel stains and top coats (Satin finish) on my McCobb planner.

I didn't really care or need to get an exact match, but I came very close anyway to the tobbaco finish. Good luck and be thrilled you only have to redo the top!

Hal,

You shouldn't have to do a lot of sanding, if any, if you properly chemical strip. I can't tell by the pictures too closely, but the majority of the damage I see is to the top. I haven't really inspected one of these desks too closely, but I would imagine you could separate the legs and the cabinets and be left with just the desk top? If that's the case, and you want to refinish, I'd suggest taking it apart and then stripping the top. Sand only to remove scratches, dings, and other things you can't steam our or repair another way.

If you're new to this process, I'd personally suggest that you get some Citristrip and some cellophane or thin, plastic wrap, like a cut up trash bag. Slather the piece in the Citristrip with a brush and then wrap it in plastic. Try to make sure no air can touch it. Leave it like that for several hours. You can test a portion to see how soft the finish has become, and, when satisfied, simply scrap it all off with an edge knife or other dull scraping tool. It should easily fall away. At this point, wash the whole thing with mineral spirits, let it dry for a day, and then proceed to deciding how to finish.

Of course you can use a stronger product for quicker results, and there are many out there. But if you're apprehensive at all about any of this, I'd suggest taking it easy and using something that is, at the very worst, going to make a slight mess. If you follow those instructions, it should be fool-proof. If you merely attempt to sand the finish off, you're going to get worse results and risk forcing the finish into the wood. Save your time and energy and just strip it down and keep it original as possible.

If you want it to look brand new, then don't do this yourself. Even good refinishers have problems getting this finish correct. Any stain from a can (Minwax, Cabot, Sherwin-Williams, etc.) will look too clear. This will expose too much of the wood grain and not be true to the original finish. The original finish does not highlight the grain like modern stains do. Go with your gut and appreciate the honest wear and tear that your desk has. Believe me, it's too easy to tell when McCobb pieces have been refinished.

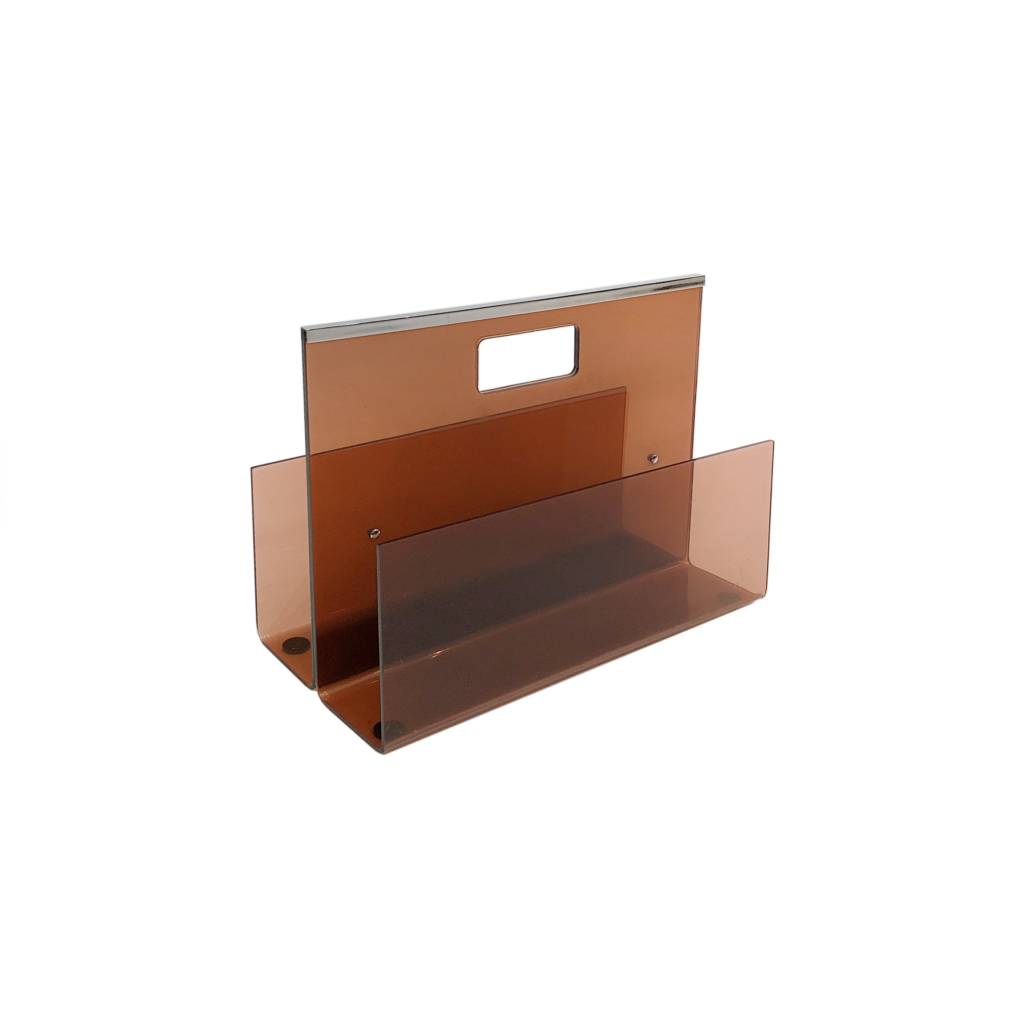

Do you see how you can see the individual boards on this desk? Do you see all of the variations in color of the wood? That's because this desk has been refinished. Your desk has a nice even finish that is uniform. With your desk, the finish sits on top of the wood but new stains soak into the wood.

My observations agree with muehlebach's. Let's face it, Winchendon was not particularly choosy when it came to matching individual boards for grain and color when gluing up panels for Planner Group pieces. From what I've seen, I suspect they didn't pay too much attention to species, either. I'd almost swear I've noticed a mix of birch and soft maple in some.

Certainly, though, the color is in the finish. I imagine the panels were originally sealed with an initial coat (possibly shellac) and then sprayed with a toned nitrocellulose lacquer. This was the common practice in high-volume production at the time to help mask variations between individual components, as the finish is translucent rather than transparent. Accurate replication by staining bare wood is simply not possible.

If you need any help, please contact us at – info@designaddict.com