No clue but maybe a lead

Sorry, as I live in Europe, I have no clue.

A little search tells me that there are some in cleveland forest. So maybe the nearest sawmill...

Also, the here this society based in San Diego that document and promote the use of Black Locust.

Maybe you should ask them.

Anyway, I guess the link might be interesting for our friends woodworkers on the forum.

http://www.asla.org/uploadedFiles/CMS/Business_Quarterly/ASLA_Black_Locu...

.

The Cado units were made from teak, rosewood, walnut and oak.

I actually used mahogany for my rails since i had it on hand. You can blend any store bought stain and mix then in small test amounts to get what you want.

Start with as little as a tblsp of what you think may be close and add small drops in any direction. Test and dry as you go. Dry state will be very flat looking. Just swipe with a cloth, with a bit of clear shellac, to see final color match.

All woods will stain differently depending on its age or cure. Just look for a clean, tight grained, clear stock hardwood. And tell the lumberyard or supplier what you will be using it for and what you wish it to look like finished.

Of corse lots of variables.

By the way rockland

Of course, one can achieve a color match with any wood, and my stain would have a different formula if I had bought my locust at a different age of cure.

But to the best of my knowledge (and I searched thoroughly though I'm no specialist) there is no wood so close to teak in veining. And teak sure have (or I should say had, because lots of what you can buy now has grown so fast) a beautiful veining.

Anyway, I'd be happy to see pics of your future project if you ever use BL.

Cheers

following my post

on the « last thing u made » thread, here's what I can add

- cado dimensions are very straight. But we forgot something. We put our rails perfect parallels, but the wall were not straight! So we had to recut 2mm of a shelf between the sliding door cabinets so it would fit between.

- Staining was a real nightmare. I first went with the staining idea because I was looking for a precise colour (teak with a 50yo patina) and my test with mixing oils was too far from my goal. Worked well with the oak floor, but not with black locust. After the staining shop made a perfect sample for me out of a vanity arm support, I realized a few weeks later, testing the stain on a spare part of black locust, that it completely lacked the reddish hue that was on the sample. So I returned to the store, and they recooked the mix, test it in front of me on an other piece of BL and it was fine. But 3 weeks later, 300 miles away from the shop and no place to buy pigments, when came the real time to stain, all the red was gone again. I'm no specialist, I don?t understand the chemical reactions of this wood, but they sure are weird. So I was stuck and compelled to stain the whole unit and the sofa with an amber walnut tone, far, very far, from the reddish teak I wanted. Back to the store next week, they gave me pigment to add to a second coat of shellac. It was a little better, but alas, it was still badly missing red. I was a little angry, considering how difficult it is for a beginner to apply these products (wood hardener and shellac just gum before you can coat them evenly). Before giving up, I had a last (chemically compatible) idea: coat the whole stuff with a mahogany tinted wax and it worked I must say final colour is about 90% close to what I wanted first, but phew... Next time (if there is one...), I?ll cook pigments with Danish oil, I guess...

custom tints

You can custom tint an oil finish with oil paints. I usually use Formby's Tung Oil Finish and some tubes of artist's oil paints I have laying around, but you could use any oil finish with any oil paint. You can get a good simulacrum of teak this way. And you can also disappear the ghosting on teak (which happens with some of these wall units since the modules have blocked UV from lightening the wall panels).

Anyway, it is fairly easy to do, mix light on the color to begin with, and layer up to the desired color.

shelf life

I'd guess the red disappeared due to time between mixing and application. Was it stored in a light proof container (UV might be a culprit)? Was it stored in an airtight container, and how much air was in the container when it was closed (oxygen in the air might be a culprit)?

It also could be a chemical reaction in the between the oil and pigment. The oil almost certainly has chemical driers, and maybe they dried the red pigment such that immediately after mixing it wiped on red and was fine, but by the time it was applied many days later the red had dried into tiny specks and wiped right off.

It could be the wood itself, but I doubt it. UV and oxygen are both know agents of color change in finishes (and wood), so I'd guess they are the highest likelihood culprits.

Leif

For sure, it can't be oil : none was applied on the wood.

Only this water based stain, the wood hardener, and the shellac.

But all you said in the first part of your message could be it.

Frankly, I couldn't imagine 5 weeks was enough to make the mix change. (long story, but had no other real possibility, considering the stain was made miles away from where my stepfather woodworked the stuff)

The mix came in transparent bottles, but were stored away from direct light most of the time.

Bottles were actually only 85% full, and were sealed with a simple cork. So, not 100% airtight.

But that's the way they sell their custom mixes.

I guess, in the end, my begginer's foolishness is the culprit. (Though you guys on the forum help me a lot to improve my technical knowledge)

Still, they should have warned me about the facts you mention.

Chemical question for Leif

Hi Leif,

sorry if the question seems absurd but: following your tinting method, can you oil coat over shellac to correct color?

(I mean, a mix o linseed oil, mineral spirits and artist oil paint)

The woodworkers who wrote this article seem to say it's possible (unless i missed a step).

I'm still not completely happy with the final color and hope I won't be compelled to sand the whole stuff.

I used, both on the wall unit and the sofa:

a/ 1 coat of water based stain

b/ 2 coats of wood sealer

c/ 2 coats of orange shellac (the second one with an additionnal pigment mixed in denatured alcohol)

d/ 1 coat of mahogany tinted paste wax

Maybe the other alternative would be a thirs coat of shellac, but the result seems already too glossy to me with 2 coats...

Cheers

http://ebenistecreateur.fr/file/livres/Travail%20du%20Bois/242%20Fiches%...

Cado:

I don't know for certain. But I think that applying the paste wax foreclosed the option of using anything over it. Oil or anything other than more wax isn't going to stick to the wax. I think your options are:

A. More wax, which obviously can be tinted.

B. Sand and start over.

experiments

Interesting...

After your post, I made 3 experiments:

1/

a cabinet suffered slight discoloration spots after some rain drops came by the window.

A slight coat of linseed oil brought the cabinet back to its even color.

2/

Tried a blo/ms/paint mix over the wax finish of my test shelf.

Wood wouldn't drink any of it. Just bubbles on the surface.

3/

Succeeded to mix my own purple tinted wax.

But applying didn't make any color change.

I guess the wood is oversaturated with all the previous coatings. So wax seems to be a barrier to more wax.

cado rails revisited

Well, found this useful thread as well...so helpful and it looks possible...if only I can afford the cost of someone making the jig...I know the company has a few of the big machines (is it CNR table? will that help?)

Hi, just wanted to breathe a little life into this topic in case anyone had anything to add. I have given up trying to find wall supports for the cado shelves and boxes that I have and have approached a custom kitchen company to give me a quote on how much to make me some of these.

This thread has been extremely helpful and I am grateful to the participants for their input. Anyway, just wanted to throw this out there and see if anyone else has anything to add or can help narrow this down so I can afford it.

vive la cado...I am determined it will hang again!

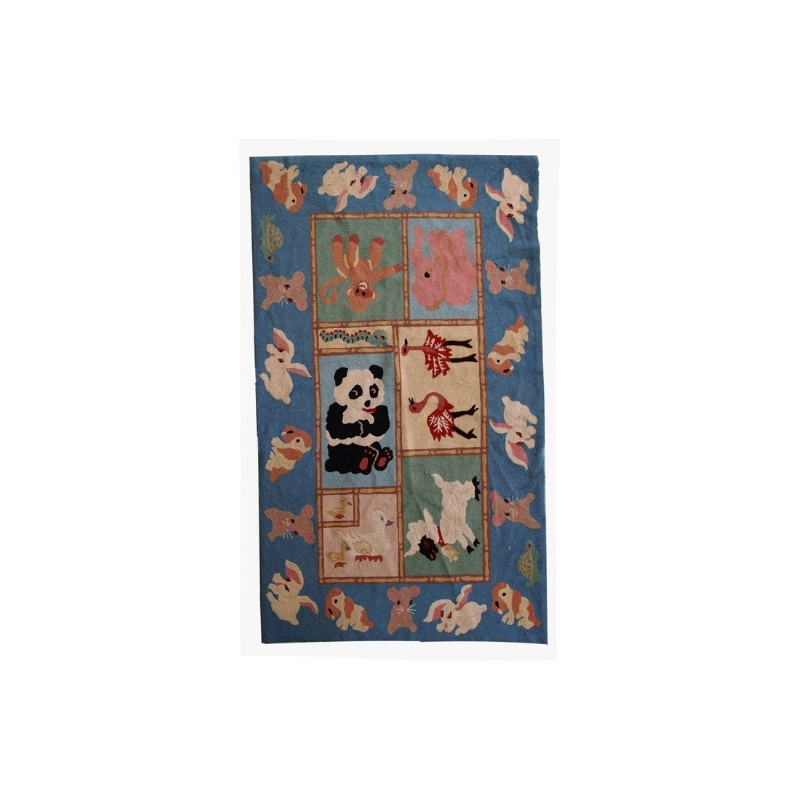

(shown in photo is an old system I had that did have the wall rails. I have basically the same again but without the wall straps ;( I have stored it for 10 years trying to pursue straps but to no avail...I need to get it off the floor and onto a wall!

If you need any help, please contact us at – info@designaddict.com