I think I have narrowed this chair down to being a Plycraft, but still not 100% sure. I have yet to see a full molded back with this shape on the internet.

Looking for some input on whether or not I should spend the money to have this refurbished. I found the chair at a local pawn shop for $50. To refurbish (refinish wood, bushings, padding and upholstery) in naugahyde would cost $700, another $200 for leather.

I am mainly looking for a piece that is relative to the era of my home and design, and comfortable, but also don?t want put that much money into something that would not be worthy. I also can?t justify the $2,000 to $3,000 for a Herman-Miller.

Appreciate any input. See link for photos.

http://www.flickr.com/photos/63979231@N00/sets/72157600321129085/

You can get better

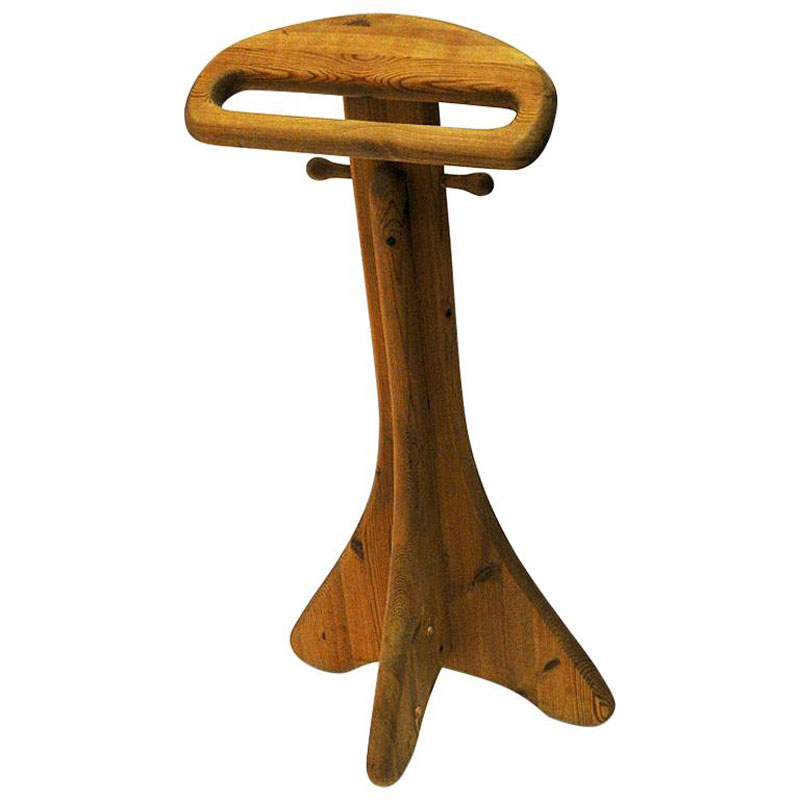

HDT - The wooden base is a clear signal that this is Plycraft. This looks like a transitional design by George Mulhauser, who did a number of the lounge chair designs for Plycraft.

50$ is cheap, but I think you can get better examples of Plycraft works. Mulhauser did some very distinctive lounges that evoke the Eames 670 without actually copying it. Conversely, Plycraft also produced a bunch that were almost dead ringers for the Eames.

If I were you I would hold out for something more indicative of Mulhauser's quality. Some photos below of two of his better works. Both show him adapting the plywood shells of the Eames into his own unique forms. I think the extention of the shells into the armrests is a really nice touch. The last is a photo of my old lounge chair by Plycraft - which is a very close copy of the Eames.

PS. If you're near Boston I've got a source for you for some good stuff.

DIY

These chairs are easy to reupholster if you want to save some money. I have done four and have another waiting to be done.

There's no sewing involved. All you need is an electric staple gun, scissors, welt cord and buttons to cover. I typically put about $200 into it ($150 for a 50 sq ft hide on ebay, the rest for replacement foam) and a couple of days' work.

I used to wish for a real Eames lounge chair but then I heard that a lot of people find the Plycrafts more comfortable than the Eames chair, so now I'm going to hold onto it and put my money into other things.

There's a big long thread or two on this board about reupholstering these. I'm sure it'll pop up if you search 'plycraft'.

Reupholstery help

Hey Spanky,

I know this thread is quite old but I'm reupholstering a mulhauser plycraft chair right now (one like the second picture). Since you said you've done a couple I thought i'd ask for some advice on technique. I am having great difficulty with the arms and getting the vinyl leather to curve around the arm. Looking at the original the bunching is very tight around the curves, almost like little wrinkles. But when I do it I get large bunches that then create visible ripples around the edge when put back on the frame. I've read some places that heating up the vinyl allows you to stretch it better. have you tried this? have any other advice?

thanks,

Ben

You're probably using too

heavy a vinyl. Vinyl comes in many weights and with varying degrees of stretch. I've never redone a Plycraft in vinyl but I've done a few other things and realized what a difference the weight makes.

You must also stretch and staple the right way, otherwise you'll end up with ripples. Tack the vinyl at the midpoint on one long side, then stretch it taut and tack on the other side. If you're happy with this, continue adding a few staples on either side, stretching and smoothing as you go.

On the straight edges, stretch the vinyl at a right angle to the edge. Perpendicular. Don't stretch it to one side or the other.

When you get close to the curve, it's probably easiest to find the midpoint of the curve (bisect it--remember geometry class?) and tack it once at that point with the staple at a right angle to the edge. Then pull and stretch the vinyl towards this on either side, stapling as you go, in the smallest pleats possible. The smaller the radius of the curve, the stretchier and thinner the vinyl needs to be. Plycraft arm rests have very small radius curves, so...

If it's any consolation, this is hard to do neatly and takes practice, even with the right materials. And the bad thing about vinyl is that it can tend to tear. If you're lucky, you will be able to yank staples and restaple without wrecking the vinyl.

Good luck.

@LuciferSum

I'm in Boston. I'm just curious as to who / what / where your "Boston source" is...

*edit - I didn't realize this thread was from 08...

If you need any help, please contact us at – info@designaddict.com