Don't have a picture of it, spanky, but basically I just took a 3/16 (width of the spline) wrench that was about 4" long (looks like an L, you know), bent the angle open a bit more, and then ground the short end to a sharp edge. I stuck that into a file handle, and presto. So it more or less looked like a spline chisel, but probably smaller and more rudimentary, and with a sharp edge at the tip.

So yesterday I learned that if a bunch of people who do a thing for a living tell you they don't want to do something, that something probably isn't very fun to do. Actually, that's not exactly true; the last one was a little bit exciting, but that might have been because I was almost done.

Thankfully, I ordered an extra sheet of cane. On my first attempt at pressing it into the groove, the wedge I'd made completely sheered the cane. Turns out that thinner wedges are best, and that they should really be rounded on the edges. I completed it out for practice, sans glue, and it didn't look too bad. I decided to soak the remaining sheets for a few hours longer than had been recommended, which I think helped quite a bit. I also decided not to trim the cane down to shape first, and I think that was the right decision.

It wasn't exactly difficult, just really stressful because I was convinced I was going to break the cane with each tap of the hammer, and you have to move fast to avoid it drying out. The narrow strip just inside the armrests was especially nerve-wracking because the weave had the most tendency to move there.

Black lacquer may have been the right choice for finish, with how badly damaged the frame was, but it made the job a whole lot more tedious. I had to tape off all the brass and fill the groove with paper cord, then be really careful not to mar the color, as a spray touch-up wasn't really an option.

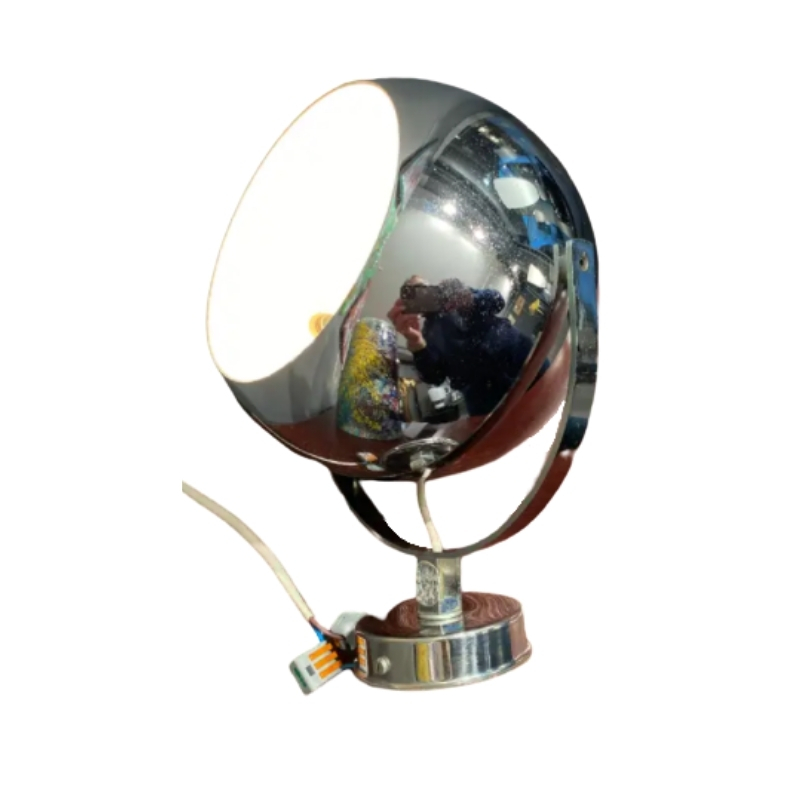

Anyway, thanks all for the votes of confidence. Here are some crappy phone pictures: the finished frame prior to caning (and aforementioned spline chisel), my clumsy initial attempt, a shot of the wedges pressed in place, and installing the spline.

Thanks! I'd been anxious about it for a couple of weeks, so it feels good to have it all finished. Hopefully the client is satisfied. It does seem kind of a shame to cover up all the nice Ash ply, but whoever 'fixed' these chairs previously really didn't leave me with too many options, even with a dark Mahogany tone... just too many screw holes and bits of damage to color in.

Looks good! "It wasn't exactly difficult, just really stressful" describes the process very well, at least until you have some experience (or so I assume--I am not at that point yet).

Some cane will dry with a grayish tint if you soak it too long but I don't know how to know for sure before you start if this will happen. Yours looks fine.

One thing that might help a bit to get the cane into the groove without it popping out again or breaking---snip or remove the strands outside parallel(ish) to the groove to ease some of the tension. If you've ever done any upholstery or covered a 3D object with paper or fabric, this is like clipping curves and trimming bulk at the corners.

I think there's a really good photo of what i'm talking about in the Caner's Handbook by Widess and Miller but I can't find my copy at the moment. Here's a photo I found online at basketmakerscatalog.com:

http://www.basketmakerscatalog.com/cane/canewebbingpics/pullingcanefromc...

That's a well-defined corner but the same principle applies to curves. You can also trim the cane to about 2" within the groove, then pull the offending strands as needed.

And lastly--this won't work on these chairs but if you ever do a seat and you break a few strands at the groove, you can weave new ones in from the underside and just leave a little tail end sticking out below. Not worth it for a lot of breaks, though. And not something that you can do when the backside shows, obviously.

If you need any help, please contact us at – info@designaddict.com