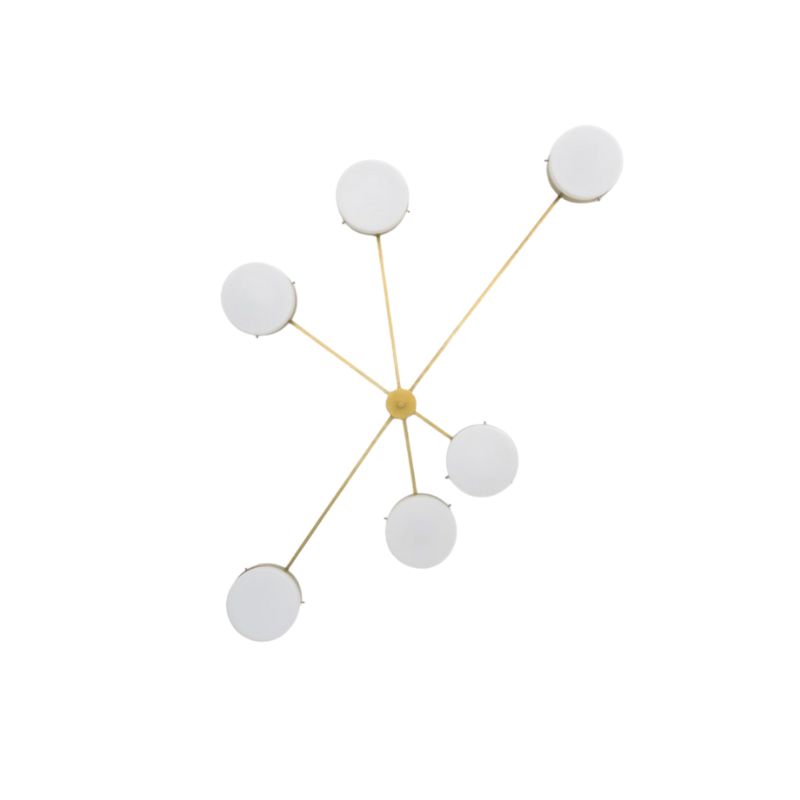

This is very rough, like the US president its evolving...I can't afford a festo domino, have always liked loose tenon joinery and think that the plans found online for router based loose tenoning machines are a bit OTT and could be a bit more elegant, this could be made with 3mm thick steel or brass strip, the same kerf as most blades so easy to cut the slots on the saw.

I hope it makes sense, X and Y axis, working on the Z...

What do you think SDR, SPD, tktoo?

Perhaps the new Veritas hold downs I bought might be handy.

I'm not quite sure what I'm seeing, Heath.

Is this something you have built?

I've seen a few shop-made horizontal slot mortising machines in articles in FWW magazine and such as well as a few commercially available examples, but I haven't ever faced a production run that would warrant the expense or time required to build one and I've only ever rarely used loose tenons.

As a hobbyist now, I prefer to mark the joints and bore out mortises with Forstner bits on the drill press fitted with a simple fence, paring to final dims by hand with bench chisels. Tenons I cut on the table saw and trim to fit with a shoulder plane. I have a hollow-chisel mortising attachment for the drill press, but I've found that if I need to cut fewer than a dozen of a certain thickness, it's not worth the set-up time to use it and those chisels and bits want to heat up fast and are a challenge to sharpen.

It seems the older I get, the less I want to use my routers if I can avoid them. Mine are very loud and make a real mess in the shop. They make sense for some operations, of course, but lately I try to use them outdoors when possible.

That stated, the machines that I've seen usually are fitted with levers to exert the force necessary to mill the work. It seems like you've got the depth and lateral stops worked out, but how do you propose to move the work in a controlled fashion? You can't cut full-depth in one pass.

With a little hunting, I might be able to refer you to some published designs, if you want some ideas.

Still, one must marvel at the ingenuity

of some that devise their own:

http://www.finewoodworking.com/item/35986/homemade-slot-mortiser-has-all...

http://www.finewoodworking.com/item/35986/homemade-slot-mortiser-has-all...

Hey

Sorry I'm late to the party.

I do quite a bit of loose tenon, and traditional, mortise and tenon joinery. I've always toyed with getting a horizontal slot mortiser...or a Domino ($).

tktoo - I hear you on keeping the noise to minimum for a change in the shop. After a long day with the dust on I'm longing for a chance to pull out the hand tools.

Check out this gentleman's site; http://woodgears.ca/slot_mortiser/index.html

back out the address for lot's of great projects.

.

Some of those home made machines look like they'd last a few months and slowly loose accuracy and tightening ability...I'll keep working on it, other than a trimmer I always keep the big router in an enclosed table with a pretty thick top, you can line the inside of the cabinet with that rubber acoustic dampening stuff used in cars.

Anyway after experiencing my fathers hearing loss the ear muffs go on for all tools other than the jigsaw, drill and lathe.

If you need any help, please contact us at – info@designaddict.com