Yes, thank you both for sharing

Now my only question is to SDR. Where do I send my check to have the prototype sent to me. No need to finish it, I got that covered, and of course I can wait till you make a second copy while you build your final jigs and take your completed item measurements. I very much like it in the poplar.

I'd love to post a project

but next to Heath and SDR's efforts, I'm afraid it would be akin to being asked to go on stage at the Met and sing with Placido Domingo, and I'm afraid I can't carry a tune in a bucket. Both of your work is exquisite in both design and execution. I am humbled. :-0 🙁 🙂

Thanks all.

Yes it was I who mentioned plywood first -- guess I've talked myself out of it ! I suppose any material will get beat up around the edges, but even European-style multi-ply can get ratty eventually if dropped on edge a few times. These tables will probably be set on a brick-paved patio, slightly raised and separated from the sidewalk by planter boxes and covered by some sort of translucent canopy in the rainy season. Access from the sidewalk is a short ramp to one side. The area is only about 15 feet square, so 5 or six tables (the others will be used elsewhere in the establishment, indoors). The folding procedure involves tipping the table onto its long side and triggering the catch (without it the table collapses when lifted); even with the bumper glides I've attached to that edge of the top there will be accidents and damage.

I like mahogany -- don't know why I haven't gotten to that. Now to look for some cheap. I'd love to forgo any finish in favor of an occasional sanding. But that might be a faulty idea. Some finish will make daily cleaning easier and more effective, I guess.

The whole thing is a little too refined and precious for a clean-and-sober non-profit staffed by volunteers, maybe. I'm going to think about "knocking myself off" with a cheaper and easier product, before I commit to these. First thing: see of Outwater Plastic Industries still offers plastic one-piece continuous hinge, which would probably be stapled to the wood [ducks head to avoid thrown bottles, eggs and fruit] !

I suppose I'll retain this poplar prototype. Wish I'd selected color-matched stock for the base. (That suspiciously-even blond stripe on one leg is a repair -- the piece got too narrow while cutting, so I added wood and made a stab at matching the other leg while I was at it.) I could be talked into making one for a DA member. I'd like a beefier elbow catch; there's one out there with the "rooster" cut from a solid metal extrusion, I think. The latching is really quite satisfying, I must say. . .

sdrdesign@yahoo.com

someone mentioned cedar, I th...

someone mentioned cedar, I think that would be a good choice but might cause it to look a little too much like a picnic table, how about enamel paint or if its staffed by volunteers let them do the finishing and assembly. Might save you a little time and money.

Cedar

A picnic-table look is OK by me ! See link.

I bought some cedar for the first time recently, to repair the sidewalk bench I made. It seems to grain-peel a bit less than fir, so might make livable edges. It would weather well, of course. Now, to finish or not to finish. . .?

http://savewright.org/wright_chat/viewtopic.php?t=2484#2484

on a tangent I picked up this...

on a tangent I picked up this old woodwork magazine a few weeks ago and found this article on Lee Sinclairs 'convertables', suprised to find they are still in production, thought you might like them. The price is a bit of a shocker though.

http://www.leesinclair.co.uk/converta.htm

Thanks

I'd never seen his work. The Conver-table seems to have a connecting link between base and top. . .?

I like the chunky high-back and tub chairs, too.

http://savewright.org/wright_chat/viewtopic.php?t=2510#2510

The leg

might be less odd in the horizontal position (and less likely to be a "tripper" ?) if it were tapered from the X-member; this would give it a shape that would also look good (I think) in the vertical mode, tapering both toward the floor and upward as well. The finial molding to the leg now is hard to justify, to my eye.

(The foot I added to my own table -- which I am calling TAble, because the legs are shaped like a T and an A -- is more of a serif, I think; it gives a better land for the glide and helps balance the visual weight of the top, as well as securing the structure by crossing the grain of the leg proper. It is, nevertheless, dispensable. . .)

Here's

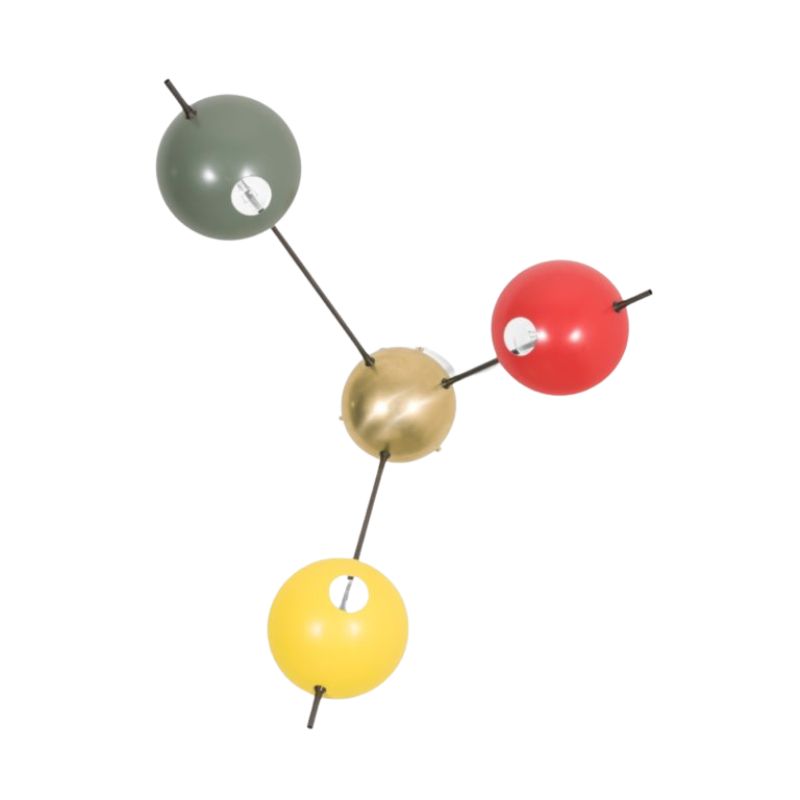

a table I did as a make-work project for my last employer, using scrap teak and a salvaged round glass top (not shown). The central intersections are made with long dowels; the other joints are generously splined. I try to use dowels only when they can be pinned mechanically, or glued into grain which is parallel with them (as in this case) -- or when they float, as in the TAble. Dowels as used in typical furniture joints ("this sofa made with dowelled joints !") are suspect; they are usually quite short, and the portion which penetrates cross grain has very little good glue surface; the dowel is essentially glued to end grain for most of its circumference. This is why old chairs of turned wood sometimes come apart at their intersections.

The slow part

for my (new) mac is waiting for the thread to load. ATT DSL -- but it's not bad, really. The all-picture threads (I guess 100 posts per page is normal ?) -- like "Name that building and architect" at archinect -- are a pain, that way. But they have a "go to bottom of page" button which eliminates the scrolling. . .

.

loads fairly fast for me even though I'm running vista which I can find nothing good to say about it.

I love the teak, I just went up to the reclaimed timberyard here and got a beautiful piece of 'rosewood' (the australian stuff, still lovely) for only $8.00 a metre, its pretty much dressed and I will definitely be going back, just have to have a long hard think about what to do with it.

Now don't you think that teak table would look lovely with a round-over 🙂

Certainly.

The thing is, you have to decide what to do at the inside corners. I guess your technique would be the best -- there's certainly enough material here to "waste" !

Then, you have the problem of how the radius resolves at the center, and how much to do before assembly. But having problems to solve doesn't mean the proposal is invalid.

If you need any help, please contact us at – info@designaddict.com