Hi or Moin, as we say in Hamburg.

My name is Bernard and i am a student for mechanical engineering. So you may be thinking i am a designers worst enemy. What the hell am i doing here. It's easy. I love good design and i am rooting to become an eginneer who is willing to sacrifice some of the rigid easy to manufacture aspects of my concept for a better design. I will always try to get a nice compromise between these two.

Enough introduction here comes the first part of my story.

I was installing some stainless steel decorative strips in a hotel near Hamburg St.Pauli. I noticed a table and thought it look nice and that i could make one for myself easily. (I added a picture) So i started investigating it. Trying to uncover the secrets of its manufacturing process. I noticed a few things right away. The welding spots were selected poorly as they broke the clean look of the table. And it was cut on a lasercuter, but it wasn't designed to be cut on one. The leg shape consists of splines, which can be hardly without leaving some sharp unwanted corners.

I knew i could to it better. Take the Design and make it properly manufacturable. So i did! I removed the splines. Made the shape entirely out of circles (A PAIN IN THE ASS). I made sure to hide my welding spots properly. Did my research on how to work with wood and what i have to consider.

I will manufacture the first table hopefully this week and see how it turns out. It will also get powder-coated which is awesome!

If you would like to know more, or see the progress of the manufacturing please say so. If you find mistakes please tell me, as this is the first english text i've written in like 2 years 🙂

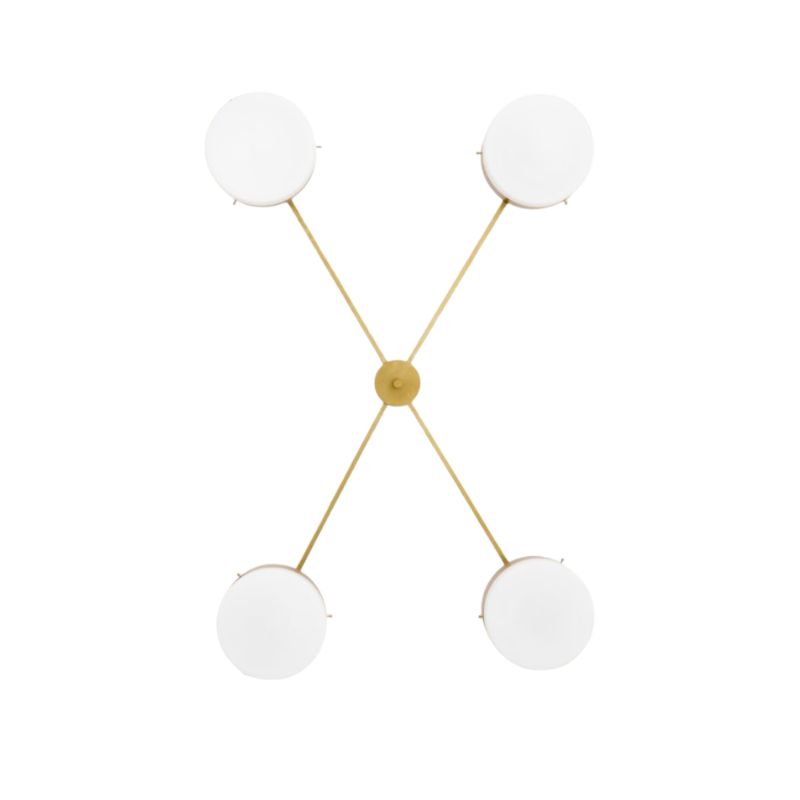

I also added a few CAD renderings of my Design tell me if you like it.

Yours

Bernard Covic

<img class="wpforoimg" src=" http://d1t1u890k7d3ys.cloudfront.net/cdn/farfuture/uxCqgDA-7lcw

<img class="wpforoimg" src=" http://d1t1u890k7d3ys.cloudfront.net/cdn/farfuture/uxCqgDA-7lcw

You will need to account for wood movement with the solid oak. You want the grain running the long way. You can screw the oak to the apron, as drawn in the center of each end. The long front and rear edges will need some flexibility at the mounting points so that the wood can expand and contract with humidity changes.

One option would be to mount the top at only 4 points, at the center of each side. Then the long-side apron will flex as the wood expands and contracts.

If you don't account for wood movement the top will split or buckle.

Also, you will want to use quarter sawn oak for this top. Flat sawn oak is too likely to warp.

@tktoo Hey thanks for the review. I appreciate it a lot. As you can see i did not have any studio art classes :D.

@leif ericson i did account for the wood movement. Talked to like 5 carpenters about mounting solutins the solution was to make the holes a bit wider than the rods inside them and glue it together as the glue will allow the wood to move, this way there should not be any spliting or buckleing. It is my first piece of furniture even if it splits i will learn a lot from it. Also Thank you for the Time you spend on your comment

In english: This forum is mostly about danish mid century design so your table probably doesn't really match the tast of many including me. I personally would back tktoo but it's your table, do whatever makes you happy.

So viel, damit die anderen sich nicht ausgeschlossen f

"People buy a chair, and they don't really care who designed it." (Arne Jacobsen)

@Herringbone Wow thanks for the reply. I never expected such a detailed aswer.

Der Tisch hat wirklich sehr wenig mit d

If you need any help, please contact us at – info@designaddict.com