So today i was walking around in a flea junkmall in PA Amish country and came upon an arne vodder small sibast sideboard carcass for next to nothing.

the legs on it are not the original and its missing all drawers and doors. But the cabinet box is in good shape with no chips and just needing a light sanding and oiling. There is no Danish quality control emblem or foil label, just the branded sibast mobler on the backside

i am going to clean it up, fix, re-purpose it for my girlfriends small apartment as a media cabinet.

my plans are to do plywood doors with colored laminate but on the legs i was thinking of replicating the brushed metal versions with wooden bottom inserts, most likely a soaped oak.

can anyone post up dimensions and photos of the legs if they have a sibast sideboard and also photos of the type of hinges they used on the doors?

Started taking the non-originals off like legs, etc. The junk has been on for years and it most likely was a pickers barn find judging by the mousing droppings in the crevices.

the past "fixer" put a plywood panel on the bottom and a vertical divider and at one point a shelf which he nailed from the outside in. i pulled the nails all the way through as i figured if i tried to back them out it would splinter the veneer

the back panel has a crap ton of holes drilled into it. at least there was a rhythm to their madness and its organized. the only problem is that when they blew through the inside of the back panel prob with a spade bit, it shredded the veneer and wood of the center core. but from the backside it looks clean. what are my options here? What i was thinking was to re-veneer the inside of the panel and then re-drilling the holes from inside out so its at least clean cut.

i

Do you care about keeping the marks in the upper right corner?

If so, you might consider replacing the plywood in the areas with holes. Find baltic birch plywood of the same thickness. Slice out the areas top to bottom on a table saw. The route a tongue and groove joint along the edges and glue the panel back into one piece. If the plywood is too thin for normal tongue and groove bit, you could create the groove with the kerf of the table saw, and the tongue with rabbet cuts on a jointer (or table saw).

Can you replace the bottom of the cabinet with the correct species veneer?

A pair of bypass doors in Vodder's white and yellow would look great:

http://www.liebemoebelhaben.de/objects/object/?id=803

(If you want to do folding doors, the hinges I see in photos are brass piano hinges, so not hard to find...)

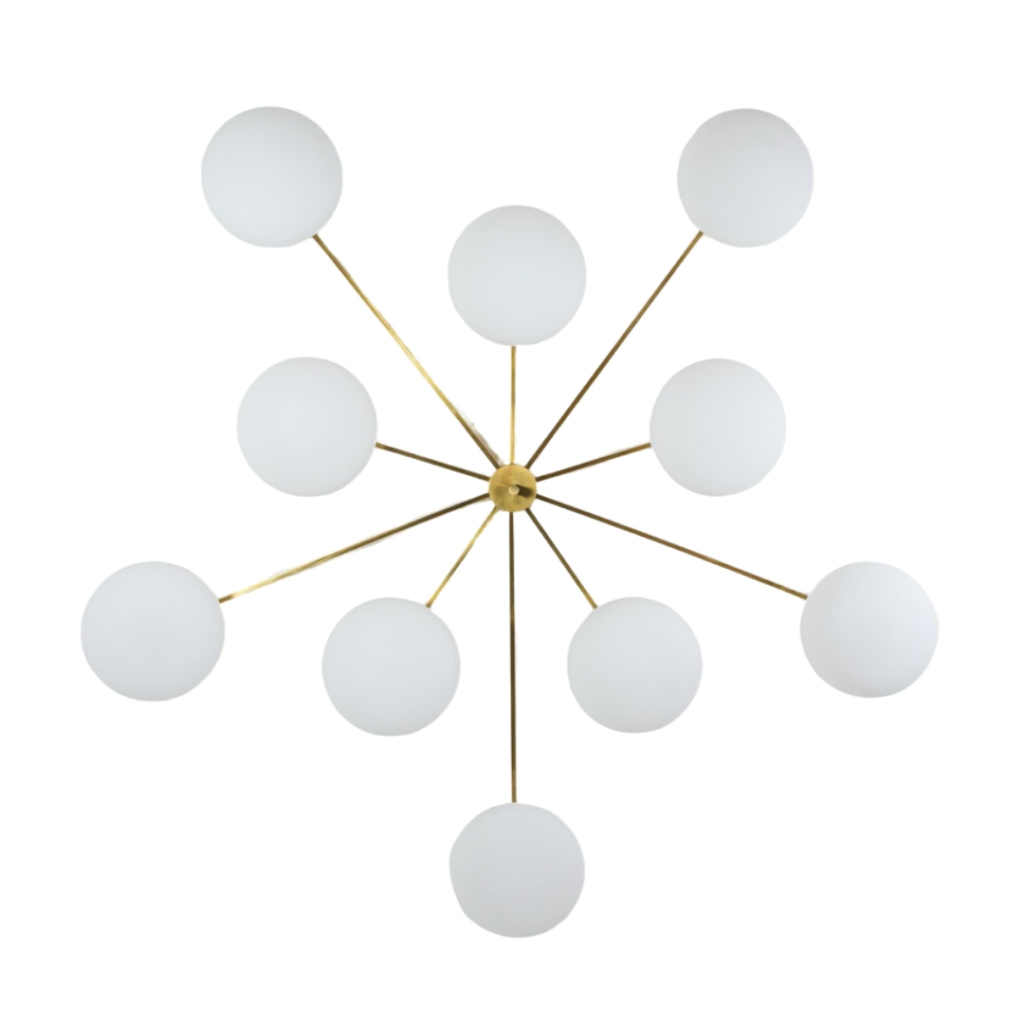

Here is a good view of one of the metal legs:

http://www.lauritz.com/da/auktion/arne-vodder-skaenk-for-sibast/i872934/#

Final point about those feet. The wood expands and contracts, the steel does not. So the naive solution of making the wood a tight fit inside the pipe will not work reliably. In low humidity the feet may fall right off if you lift it up.

I don't know how Sibast solved the problem. If you want to be accurate you may need to find a foot you can remove.

I can tell you how Johannes Aasbjerg solved the problem, but there is no guarantee that it is the same as the Vodder/Sibast solution.

i do want to keep the makers brand/mark. Is it Baltic birch? the back panel is not just a flat sheet of plywood. Its not even plywood per say, ill post a picture up but the edge is stepped and you can see the core of the plywood and it is vertical 1/2 solid strips of some type of wood and then has thicker wood veneer over front and back.

the bottom panel that you see in the photos is not the real bottom. it was an add on by the last "fixer". i pulled it up and the wood underneath is not stained but does have holes from the holes from nails and lag bolts from the legs. the odd thing is that there is not a matching veneer. i am starting to think that this sideboard was a tambour door variant from the lack shelf holes and no evidence of groves hardware for the sliding doors. and there is 2 holes drilled on the underside of the top and they are inline and not offset

On the subject of the legs i was thinking of modifying ikea capita legs by cutting them to length and then turning a stepped dowel to fit inside the pipe and be flush on the bottom side with the outer diameter.

what would you say the thickness of the doors are? seems to be thicker than 1/4 inch in all the photos ive looked at and not quite 1/2.

my GFs parents have left over boards of old growth Cuban mahogany that was removed from from a 60s mid century add on to their restaurant building was vacant that they just expanded into when they remodeled. so maybe going to be doing something with that on this project

If you need any help, please contact us at – info@designaddict.com