I struck out on ID'ing my Danish flip-top table, but plenty of people looked at it in an attempt to assist, and I appreciate that.

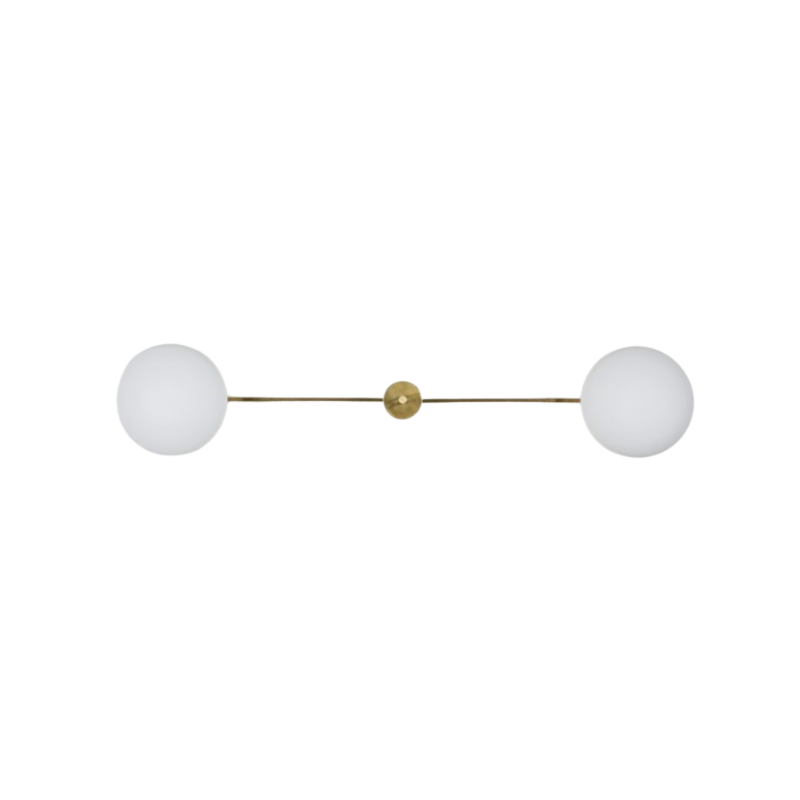

My next quandary is missing hardware from a Sigvard Brnadotte 132 chair. It uses these little brass ball hinges which allow the backrest to pivot. They presumably with a loose post captive between the two hinge pieces. I'm missing half of each set, and wondered if anyone knew where these types of hinges might be sold. I've included pics of the back of the chair as well as a Peter Hvidt table which seems to use a similar hinge. Thanks in advance!

.

I've never seen a hinge like that in all my goggle seaches for brass fittings but ball nuts and ball headed machine screws are pretty common, if you could find something close a jeweller with a little lathe would be able to drill and if necesary tap the holes you need for a pin pretty easily.

Its a nice fastener, thanks for posting it.

These could be made easily

Threaded brass balls of various sizes are sold. And some of them have an additional side tapped threaded hole.

So buy the threaded balls in the appropriate size, buy brass threaded rod, and buy brass rod that just fits inside the threading.

The threaded rod gets cut to size with a hack saw and attaches the ball to wood (going into a threaded insert). Or you might find a table leg screw with machine thread on one side (for the ball) and wood thread on the other.

The brass rod without threads gets cut to size to fit between the to balls.

Simple to make, requiring only a hacksaw. And should be virtually identical to the originals.

I am curious, is there a threaded insert in the wood? Or does the ball have a wood screw shaft that screws in?

I've been thinking about...

I've been thinking about these again since being taunted by a recent post of the bottom of a France and Son coffee table that appears to use this same part on the lower shelf (post title "france & daverkosen / Sons").

The best way to describe the part would be through a pic, but the basement is in shambles due to other projects, so it'll be a few days. In the meantime, I'll attempt to describe:

The brass hinge is attached via an internally-threaded post and a screw (like a cabinet knob / pull). The ball has a non-threaeded hole drilled in the side, presumably for a short length of brass rod (as you suggest).

The URL I've referenced is for the closest thing I could find commercially. The trick is drilling an accurate hole on the side of the brass ball... I don't have a drill press, so it's not an easy task.

I'm not certain what you mean when you talk about the threaded brass rod; perhaps you can elaborate?

I know I could easily solve the whole issue with a trip to a machinest, but I'm trying to keep the costs down as the chair I have is already in rouch shape (loads of tiny holes from upholstery tacks in several locations) so it's kind of a labor of love at this point and probably not suitable for sale or trade.

http://shopping.yahoo.com/853055563-baldwin-1090030i-polished-brass-set-...

Leif - you're absolutely correct

I re-read your post and googled about and found something that will likely work perfectly, just like you said it would. I'll find something like the below and play around with it and post my findings.

http://www.grandbrass.com/SearchShowItem.cfm?ItemNumber=AB390

Oh and

Holes, especially in teak,can be patched quite well with white glue (Elmer's school glue) not any of the fancier water resistant or water proof glues mixed with razor blade scrapings from the wood of the chair to make a putty, sanded smooth when dry. Using the water soluble glue guarantees the finish can penetrate well. And fine wood scrapings work much better than sanding dust and can fill a large gap even (3/16in).

Thanks Leif!

I've used sawdust mixed with Titebond with good results; I'll try some larger shavings and white glue on this one. The holes are small but I cringe every time I look at them because: a) there are about a million of them, and b) the tacks they used were galvanized / zinc plated so they have that lovely black halo around each hole.

It'll be quite a while (perhaps the fall) before I get to this project, but I'll do my best to capture before and after pics to share.

Thanks again for sharing your knowledge!

Try oxalic acid

for the black halos. It is likely to reverse the tannic acid & iron blackening you are seeing. I have seen it work quite well so it might completely remediate the blackening. You get it at a paint store. Often sold as "wood bleach" in a plastic container as crystals, and the small print will mention "oxalic acid."

I have a hvidt minerva side table used as an outdoors table by the previous owners. It required sanding and oxalic acid treatment on the top to remove a wide area of this blackening. (Water on wood can facilitate the creation of ferrous tannate from tannic acid and iron naturally present in the wood). The only ill effect of the oxalic was that a bit ran over the edge and lightened a small patch of the underside, which is only visible from certain angles and in certain lights.

I would apply it before patching the holes. Might take a few applications to complete its work. The holes will allow it to get quite deep into the wood so I'd monitor the situation excessive swelling and if necessary apply it so as to keep it out of the holes. But this is teak, not oak, so probably not a huge concern. Perhaps rub the wet edges with a cloth to guarantee a feathered edge (which would have eliminated the problem I had). And it will raise the grain so sanding/razor blade scraping will be in order. But that is already on the menu anyway.

oh and back to the initial question

The name of the brass ball with two holes generally seems to be "armback" and is sold by lamp parts supply houses. (Google it an you will find a wide variety).

And for what its worth, I believe the actual hinge is probably called a "screw hinge" or "drive-in" hinge. If you google that you will see a variety of similar hinges, but they tend to have cylinder shaped heads instead of spherical. The hinge might also be classified as a specialized sort of "lift-off hinge." None of those terms allowed me to find exactly the hinge, but maybe it will help someone else.

More solid suggestions,...

More solid suggestions, Leif, and I thank you for them. I'm going to sand the chair down to bare wood anyway, and on previous experience that has sorted out the black marks, but I'll dig out the Bar Keeper's Friend if sanding doesn't do the job.

All this conversation is tempting me to move this project to the front of the line...

If you need any help, please contact us at – info@designaddict.com