Hi,

Does anyone here have any good tips on how to repair smaller dents on an aluminum lamp shade, that doesn't require filling the dent and completely repainting the whole lamp?

I have a few lamps in need of some tlc, but I would prefer to leave them as original as possible...

I've been reading about different methods to handle dents on cars and motorbikes, such as pressing the dent out with special tools, or heating/freezing the dented area to get the dent out, but the aluminum of a lamps shade is much thinner of course, so I'm a little afraid of trying anything to drastic, thinking I might damage it further instead...

Has anyone tried any of these methods or know of other solutions?

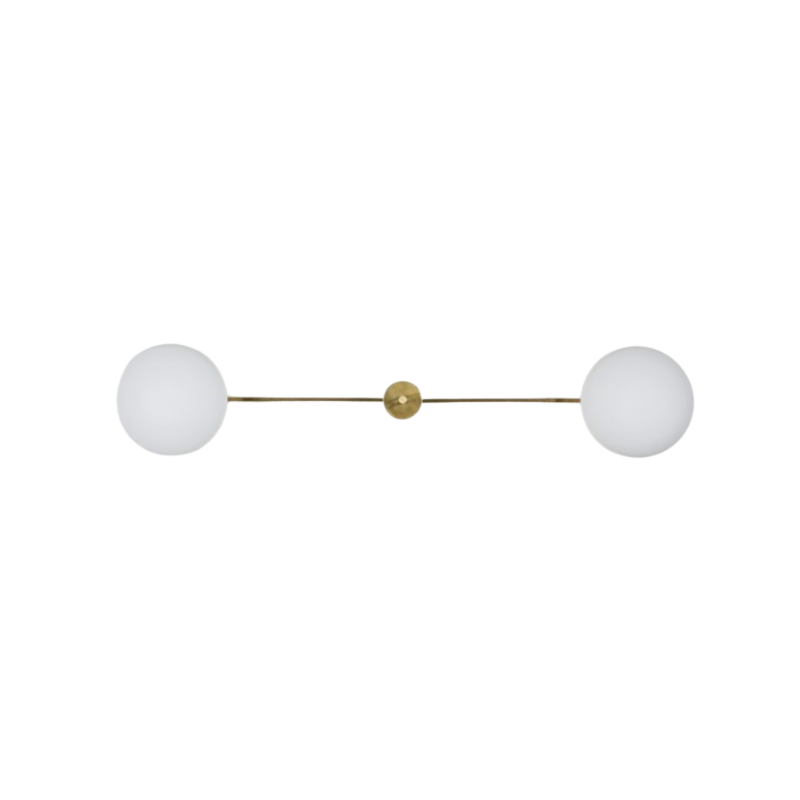

Sorry for the tiny pic...

Thanks Jim, that does sound...

Thanks Jim, that does sound like something I'd dare to try. I could start to work the dent lightly and then with some more strength if needed, and if I dare...

Jim, do you have before and after images of your lamp?

I've noticed you have quite a collection of aluminum lamps, -I especially like the Rietweld Panama wall lamp.

I will have to look into Nico's suggestion as well. I hadn't heard of that technique before, but I've seen youtube videos of people repairing cars, popping dents out, by first applying the heat from a hairdryer and then spraying the area with compressed air to cool it down. It works on car fenders, but I'm not sure if this would work on aluminum too...

Now I just wish I had a few spare lamp shades that I didn't care for, which I could experiment with before applying my skills to my more treasured pieces...

Sorry about the image, it showed on the screen of my other computer, but now it's gone...

Never heard of all

these fire-and-ice metal repairs -- most interesting, if true. Sounds more like mumbo-jumbo or wishful thinking -- but then, what do I know ?

I restored a smallish half-dome aluminum shade 50 years ago. I carefully tapped the dents out, against a cloth-covered hollow wood form I contrived -- then put the shade on a wood disc attached to a motor (like a home-made small lathe) and spun the dome at moderate speed, using a hard sanding block to locate the repairs, now slightly proud of the surface. I'd stop the motor and sand down any high spots, then resume the spinning with fine sandpaper to replicate the original brushed finish. Came out great.

Never heard of all

these fire-and-ice metal repairs -- most interesting, if true. Sounds more like mumbo-jumbo or wishful thinking -- but then, what do I know ?

I restored a smallish half-dome aluminum shade 50 years ago. I carefully tapped the dents out, against a cloth-covered concave wood form I contrived -- then put the shade on a wood disc attached to a motor (like a home-made small lathe) and spun the dome at moderate speed, using a hard sanding block to locate the repairs, now slightly proud of the surface. I'd stop the motor and sand down any high spots, then resume the spinning with fine sandpaper to replicate the original brushed finish. Came out great.

Sorry

but I just don't buy the dry ice idea.

There's all kinds of "advice" on the Internet -- people (i.e., those advice pages) just can't help being "helpful." But reality is what it is.

The ding is just a smaller dent. In every case, the metal has been bent -- and, necessarily, stretched. No amount of "temporary shrinkage" is going to have much effect, either on the bends or on the stretching -- to my way of thinking (which, if nothing else, isn't wishful.

So, something more aggressive will be needed. I like the idea of consulting an instrument repairman.

If you need any help, please contact us at – info@designaddict.com