Hello everybody and thank...

Hello everybody and thank you for your interest and attempts to help me.

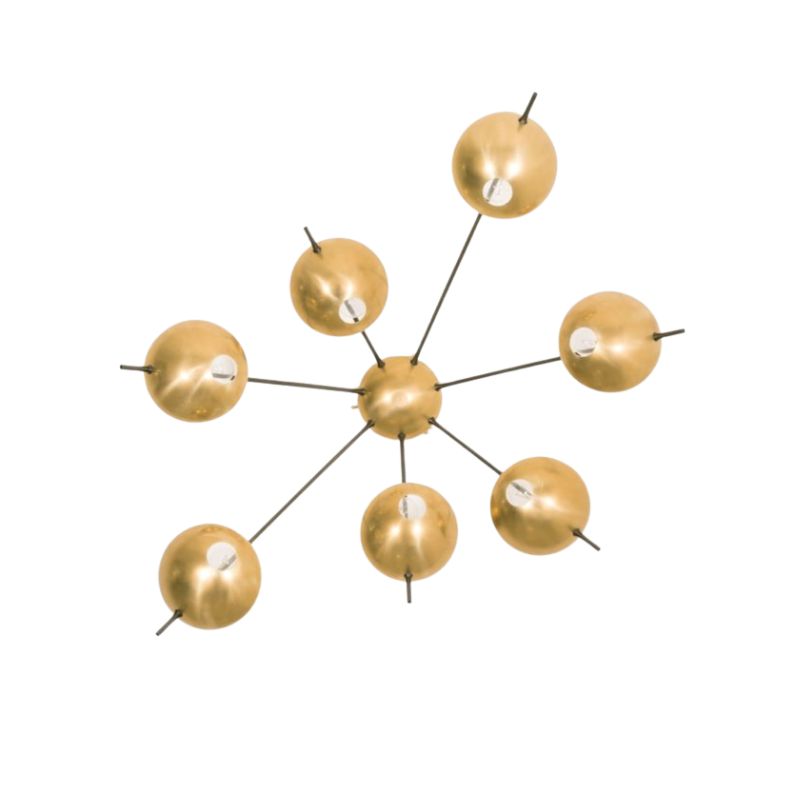

Ball, the photos I posted on the photobucket album show the bolts. That's pretty much it. The bottom part of the base is also shown on one photo. Nothing that can be seen from there as well.. :~( If you need more photos I can e-mail you some. You can contact me directly at: kevin.retrodesign@gmail.com

William, yes.. it's snap ring.. However, I can't seem to find this piece in either of my chairs.. Odd.. There is not enough space between the seat shell and the base to house a snap ring on my chairs.. Could this be a fixed version, or a swivel with altered mechanism?

Best regards and once more, many thanks to all of you

A Description

I have restored four tulip chairs and a table. As i am new to this forum, if there is still interest in how to do the restoration, post a message and i will give you a detailed explanation and supply some photos. Restoring these chairs is a big job, believe it, but when you consider what new chairs cost, even the new cushions, are incredibly expensive, it is well worth it. Zack

There is another great...

There is another great step-by-step guide here on how to restore tulip chairs with additional pointers http://www.aliceindesignland.com/blog/how-to-refurbish-a-saarinen-tulip-...

Tulip Chair Dismantling

I have obtained five Tulip chairs from 1981, with six cushions here in Northern California - for $12.00 each. The previous owner could not find the sixth. The poor chairs were left outdoors for a long time, near a swimming pool, and never covered. That the cushions are intact at all is credit to the Knoll company.These are authentic Knoll product, the USRubber cushion pads have a 1981 date on them. The vinyl pad covers are rotted, but I may be able to construct a form to create new covers. At 300 American dollars per for replacement, that is what I can do. The seats are sunbleached and stained with what looks like algae and mold, the pedestals are all chipped off the base, and some are showing 'bubbles' from Aluminum corroding. As for separating the seats. Tough job, and delicate. I was able to remove the circlips at the base of the chair (thanks to this query thread)but had to use a brass drift pin and a five pound sledge to remove the swivel hardware and shaft out of the pedestal. This worked. Next, to seperate the metal plate with bolts you find under the cushion seat. Do not attempt to cut off the bolts with a grinder or any tool that will produce heat. The screws must be drilled out if frozen. I used PBlaster penetrating oil. Didn't touch it. Use a cobalt drill bit, 3/16 or 13/64, electric drill, and patience. I now have seperate pieces to clean of heavy aluminum oxidation - the rilsan coating on the pedestals is destroyed, and I will be cutting it off to expose the aluminum casting. The fiberglass seats are in good condition, only two have small cracks and dings that ought to be easy to repair. Hoping to blog this adventure with photos, as it is quite a project. We suffer so for our Aesthetic.

Just found this thread on Google....

and want to post the link for all who will be stranded here:

http://vimeo.com/27090455

Addendum to the tulip chair deconstruction

As I explained earlier, The chairs were in bad shape. I have learned so much since then. First, Knoll will be glad to sell you a new chair - if you have the income, worth it. Rilsan coating of the pedestal is exquisite to the touch and eye. They can also sell the swivel mechanism. The chair kevin has described is a fixed side chair. The bolts are fastened through the seat plate into the pedestal itself. If corrosion has occurred, which is very likely, the bolts are frozen in place, and will never come out without damaging the base. Use the drill through the center of the hex bolt. Go only as far as necessary, maybe 1/2 inch. In this way you can remove the seat from the pedestal. My chairs have been powder coated in gloss white by a local powder coat provider. Beautiful results at ten feet. Any closer, and you will notice the corrosion bubbles. I used a green pad (delicately) then a white scrub pad to remove dirt and debris from the Fiberglass seat. From there, Bon Ami is a good cleaner. For the final cleaning, a 'Mr.Clean' white pad is good, then finish with GEL GLOSS cleaner and polish. Lovely finish to the touch. I have not repaired the fiberglass seats, as I only can use three of them out of the damaged five. I call them Age spots. The first swivel I completed is very smooth and lovely to view. I used red grease to lubricate the stem, and machined the bushings for top and bottom of the pedestal shaft. Tomorrow I pick up the final two pedestals to complete the set. I will attempt to photograph the set as finished. Saarinen original Knoll chairs are the most beautiful shape to hold and look at. Burke and other knock offs are a second best - even to a repaired Knoll original. Now for the cushions.....

Still need assistance..

Hello and thank you for the reply.

Well, if I am to drill through the hex bolts, how can I assemble the chair back together? Or if I take the bolt's hex heads off to remove the seat and the metal disk will I then be able to spray some WD40 to the remaining screw on the base and hopefully make it loose and then add new bolts after painting?

Any sugestions are welcome as I still have the chairs sitting in storage to be restored.

By the way, I found 151 N embossed on the base. I believe these are original Knoll products.

Best regards

.

Hi Kevin

Have you ever drilled into a hex bolt before?

I only ask as they are very difficult to do. And you'll know what I mean when you make an initial attempt. But if you do make sure you have a few drill bits spare and 'steady as you go'. Make sure the drill bit is watered down also. Drilling slowly into metal requires a form of lubrication in most circumstances.

As for removing the 'leftovers' only time and patience will tell with that. Worst case scenario there are machine shops that will remove it.

If you need any help, please contact us at – info@designaddict.com