i need support...........rods.............not patronising

Lit Up it seems the problem is that UK sellers can't/won't post support rods - I only contact sellers who are offering rods. I don't contact sellers requesting they break up a lot and sell rods only. I have plenty of ladders and cabinets and shelves and I'm aware of what the purpose of the rods are, and that they come in two sizes. Cheers for the education anyway.

I think robert1960 answered my question in regards to the problems of postage of rods to Australia.

In

most cases they don't need fixing to the wall.

However, a single bay might, as it could theoretically shift diagonally if it only has shelves, not cabinets.

I have such a set up in my hallway for books and they are screwed to the wall near the top of each support. (there are holes in the uprights)

Free standing shelves stability

Hi there, new to this forum, so hi!

I'm onto my second ladderax system ( the first is fixed to the wall in a house I've sold in sydney, I now liv ein Melbourne. Should have removed it! ).

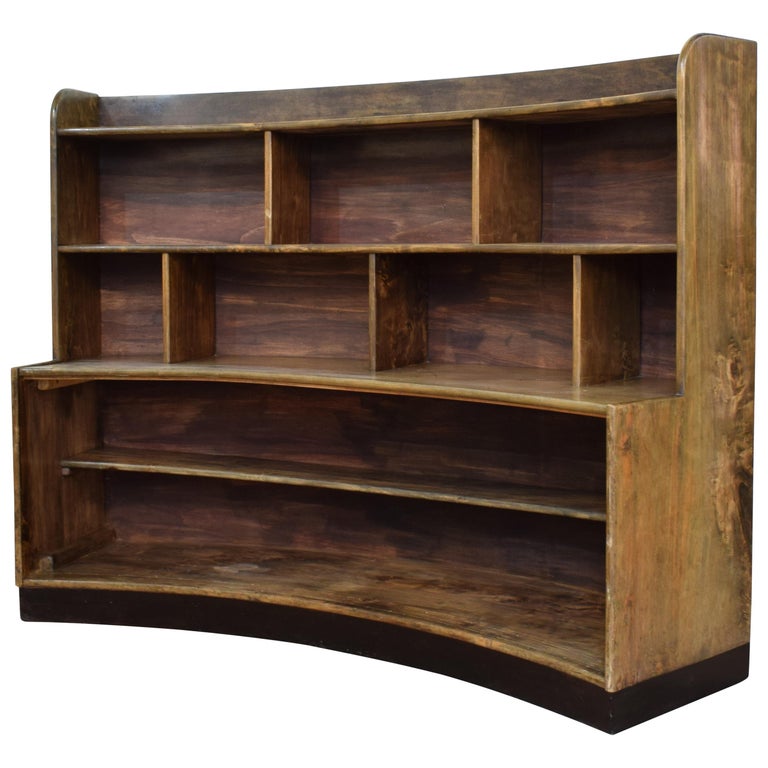

With the first system I remade all the shelves and cabinets and attached it to the wall. The system was one with triangles on the base and holes for attaching to the wall.

The system I've got now is different - it's designed to free stand so has two legs on the base and no holes for wall attaching.

My problem is this - I've remade it with just shelves ( threw the cabinets out a long time ago), put it together but it's unstable. I realize now that for the system to be stable you either need cross braces or cabinets to stabilize it.

I've got a few questions I'm hoping someone here can help me with.

1. What are the standard widths of ladderax shelves? I've re-made mine at 883mm. Any chance anyone could measure theirs for me?

2. Did the widths change over time? I've realised that some of my steel supports vary in width by about 8-9mm. This has confused me.

3. And cabinets? What are the standard widths? Again I have this at 883mm but wondering if it has changed over time.

4. Does anyone have a readable scan / photo of original literature / specs?

5. Is there any other way of stabilizing free standing ladderax?

Lots of questions I know....if there is anything I can help others with just let me know. Incidentally, I have a good power coater in Melbourne who has done a great job restring my ladders and I've also had supports remade with laser cutting and they came out very well.

Mark

Melbourne, Australia

Robert is right. There are material import codes to find if you want to export and costs due to volumetric size/weight often outweighs the cost of the item itself and then there is the issue that the amount of time and hassle it takes for a dealer to do it doesn't often pay them enough uk wages. There is also some risk of loss any seller will find it hard to deal with and the buyer could get import tax to pay at their end if unlucky.You could get non professional part time dealers who will take on sending bits abroad but those on ebay and other platforms with a second income now know they could get years of back dated tax demands on undeclared income since hmrc boosted their reach so they might not want to sell on. Roberts idea of having rods made at at local steel maker from a sample is probably the cheapest way of resolving I think.

Staples Ladderax came in 5 widths. Three can only be shelves and two can be shelves or cabinet widths - cabinets were made in two widths only.

Widths are 435mm, 587mm,740 mm,892 mm, 1045mm.

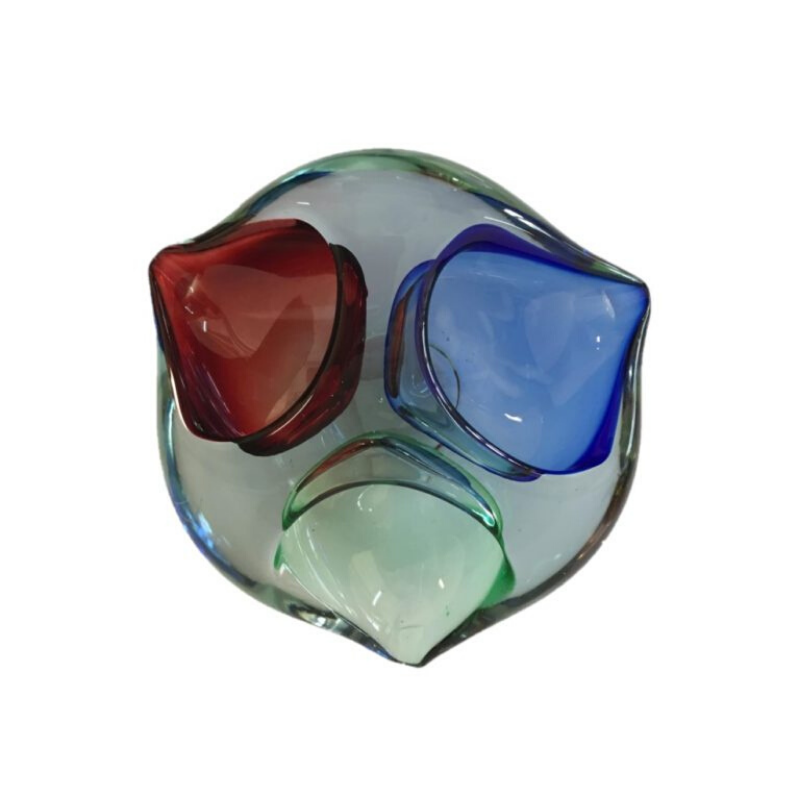

Rods are handed so they can shake hands and don't compete for the same ladder space when placed opposite each-other in adjoining bays so fronts of shelves or cabinets sit flush with the front of the ladder- why else would they be bowed differently at each end folks !

I've noticed there are lots of incomplete or slightly wrong bits of info on this forum about ladderax that don't give a user a full picture I think.

Hope this bit helps someone.

If you have room divider ladders ( with two legs) you have ladders that were designed to stand across the middle of a room to divide it and you can have one cabinet face one way and one the other- that's why the back of cabinets are ok to look at as well as the front. Wall leaning ladders ( one leg only) lean all weight back against the wall, room dividers don't usually have any holes in them unless they were for institutions who ordered them to bolt back to back to make a long row. The rule in Staples books is with room divider ladders you need to use a minimum of 3 cabinets ( with anti tip fixings) with no less than 2 bays joined together to weight it which does then halt most from wanting to fall. Any less and it can go over. The rule really relates to the taller ladders. Lower ladders this type can be much more stable. It's common sense you don't use 3 skinny single drawers for instance because it will go over with little weight. Trying to fix room dividers to a wall means you have either the wrong ladder type or not enough cabinets in 2 or more bays so it wobbles, you then have to devise something to stop it falling which could end up not looking good with your design classic.

If you need any help, please contact us at – info@designaddict.com