.

I would try cuttings some small lengths of threaded rod (booker rod) and using some brass allen "screws" (top left in the link below) on either side of the rod....you'd need 16 in all. Just wonder around the fittings aisle of the hardware store and you should find some, ask for a length of rod to suit.

If you sand off the protective coat the brass will oxidise nicely and be much less gaudy, tighten them buy using two allen keys on either side.

suggestion

HP's idea sounds fine. However I would be concerned that the body's of the socket head things might touch and lock out before some tightness was achieved. This would be due to the fact that the thickness of the wood ( and I use the term 'wood' as loosely as one can imagine, this looks like a case of sticky-backed plastic on chipboard ! ) is too thin. Off course the body's could be reduced in length but too much reduction might result in stripping the internal thread on tightening.

Perhaps a much simpler and straightforward swap for those crayzee hex-headers could be a coach-bolt ( a dome headed end with no slot or hex ) or a button head hex socket screw ( domed head with a hex socket for allen key ) which are available in stainless steel.

Or, just countersink the outer face for a flushed out engineered look with c'sunk screws.

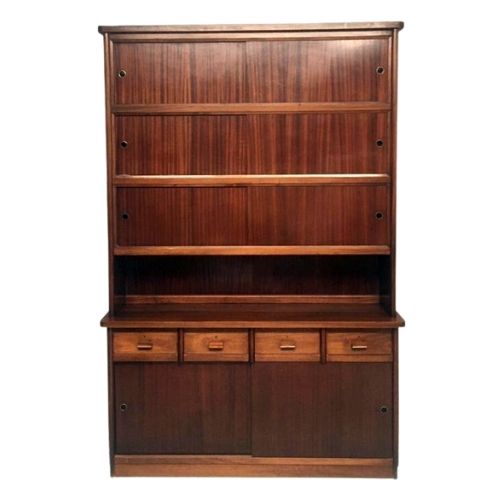

Don't fight with it. It's never gonna be a dead ringer for an Eames. Let it develop it's own character.

The Eames

lounger accomplishes these connections without visible fasteners (on the outside, at least).

I would counsel against countersinking anything into 1/2" thick plywood; the material is thin enough already.

Another solution besides the ones above would be acorn nuts with matching washers. A little bulkier than carriage bolts but more finished than carriage bolts

and more readily available perhaps than flat-head or truss-head allen furniture bolts.

If you need any help, please contact us at – info@designaddict.com