As another thread stated I was looking for a nice cross-legged table for out dining/kitchen space:

( http://www.designaddict.com/forum/General-discussion/Wich-are-most-successful-designs-when-it-comes-cross-legged-tables )

Now that or interior is slowly coming together in the new house, we wanted to add some industrial accents as we don't want everything to be midcentury. And I do like some heavy engineering 🙂

So I left the idea of the crossed leg and went on a search for someone selling a lathe, offering him/her to buy the legs.

I now have two A-shaped cast iron legs (and they are heavy) like the ones in pic, which I'll marry to a solid oak top.

(the lathe itself wasn't usable anymore)

To the woodworkers and other knowledgable people here: I plan to screw a flat metal bar on top of the legs, to attach the tabletop to.

Leif, thanks for your comment about the moving of the wood and using slots instead of holes to accommodate this movement!

I'll post a pic when I'm ready, in the mean time when you have something to add, please do!

Thanks.

Sounds like a fun project. Also, just be aware that oak moves a LOT compared to most. I used a calculator here: http://www.woodweb.com/cgi-bin/calculators/calc.pl?calculator=shrinkage and got a shrinkage percentage of 10.5%. So just make sure the slots are long enough to accommodate the expected movement.

Quartersawn would help a lot. When you look at a board and see the end grain forming a cup shape you just know what that board wants to cup. (The different tangential and radial movement percentages guarantee it). You can also help minimize the warping by alternating the curvature of the grain from board to board. With plain sawn wood, this wood mean the first board cups up, the next down, the next up, and so on. With quarter sawn, it is harder to distinguish which side was the center of the tree, but it would be cups left, then cups right, and so on. This alternation helps to average out the movement across the whole table top, so that as a whole it remains in a flat plane, even if locally it warps a bit.

Oh, and apply finish to top and bottom of the table equally. This will make the rate of acclimation to humidity equal across top and bottom.

I don't know how wide you want your boards to be, but if you are okay with narrow boards, you may be able to get less expensive, much more readily available thick plain sawn boards, and re-saw them in in strips as quarter sawn boards. (Saw into strips, rotate each strip 90 degrees, and you have vertical grain quarter sawn boards.)

Oh this is going to be a sweet table! Very nice legs, indeed! Will the finished height of the table be correct "dining height" 30ish inches? And either a soaped finish on the oak or an ebony finish would look so yummy.

Yes!

Aunt Mark

ps a half dozen wishbones slung around the table would give me the shivering fits.

bj -- good to hear from you. Has it been a while ? Great project !

I wonder if you could take a photo of the top of a leg. I'd love to see what the fastening options are; bolting the leg to the steel lathe chassis is potentially more secure than fastening at the same points to a wood top. I'm concerned about longitudinal movement of the finished table . . .

Thanks Leif for the useful comments. I will indeed change the direction of the boards, according to the grain,

to average out the movement.

Hey Mark, I was thinking the same about the wishbones! Locally 12 wishbones turned up for sale. The number is mouthwatering, but this also made the total for the chairs to high for my current budget.

I have 10 oak mollers though, model 80, but they have a more neutral appearance..

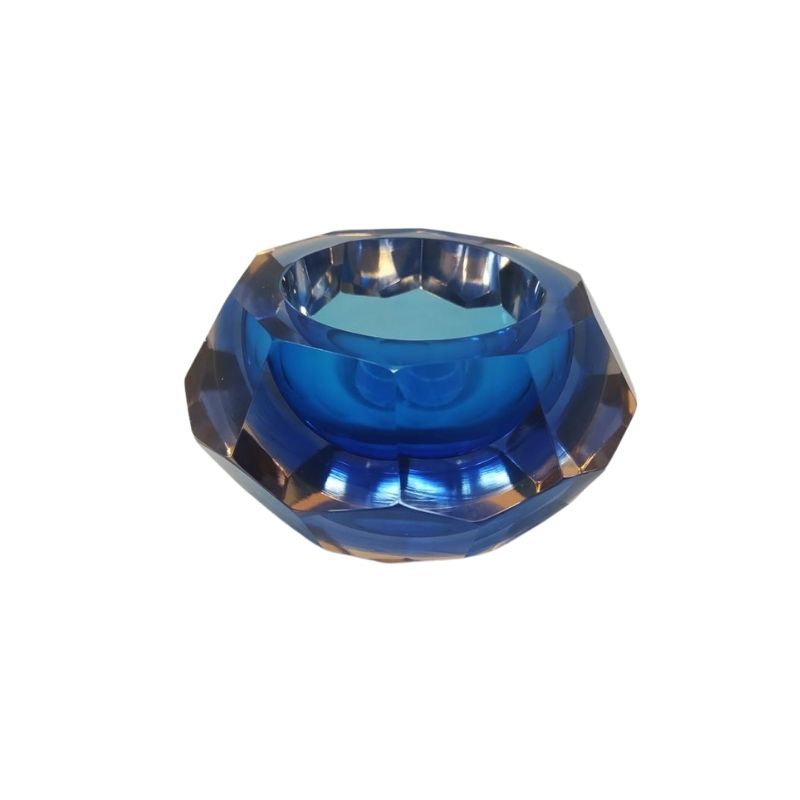

SDR, I now added a pic of my own, as the other photo was for the sake of illustration (didn't had them at home yet). It has two holes with I plan to use, bolting a flat piece of metal to.

The tabletop would then be fastened to this flat piece, through slots like Leif suggested.

I'm thinking of making the flat piece triangle shaped and making the contact surface between top and legs

that way as big as possible. I hope to address the longitudinal movement that way...

(We bought my grandparents home and did a big renovation: keep the good things, improve the outdated.

So there wasn't much time for other projects/collecting.. But now we are totally back 🙂

If you need any help, please contact us at – info@designaddict.com